Product Range

Counterforce Range

Ultra UV Cure system (UVX):

Ultra is our most popular in-house and Trade counterforce production system. The Ultra-system works very well for internal production of counterforces. For everyday embossing and debossing for short to medium run length.

- A range of UV cure embossing resins available.

- UV Cure, low energy cost, no warm up period required.

- Fast Production Counterforce ready for use from as little as 10 Minutes.

- Backing Materials: Polyester and Fibreglass in various sizes and thicknesses.

- Specialist equipment available but most UV light-based exposure units suitable.

All Epoxy Based Systems

Commercial Trade house and In-Plant product’s

- Low odour

- Heat Cured

- Very Durable

- 2-Part Systems

- 1:1 mix ratio products are in our premium range

- In-plant products require suitable jigs

- Strong bond to pre-sanded fibreglass boards.

- Trade products require suitable Vulcanising Moulding Presses

- These products are suitable for both hot or cold embossing runs

- Fibreglass Backing Boards are available in 0.2, 0.4, 0.6 or 0.8mm thicknesses

in our standard size format of 18″ x 24″ / ~457 x ~610mm.

Troy (TEC):

Troy is a super-premium 1:1 liquid epoxy resin and hardener mix with superior structural strength. It is very hard wearing, so recommended for all production runs especially high.

This product is a high viscosity, low odour and a very high specification material. Troy is very highly recommended as the first choice in professional counterforce making

Helios (HEC):

Helios is a good quality, lower cost alternative to the Troy system. This is a 2:1 liquid epoxy resin and hardener mix and requires a vulcanizing press to process and is recommended for trade houses.

The Helios system was developed to cater for certain requirement of trade manufacturers who are operating in a very competitive environment where cost is a very important criterion. Its characteristics are midrange but better then most of the products in the market.

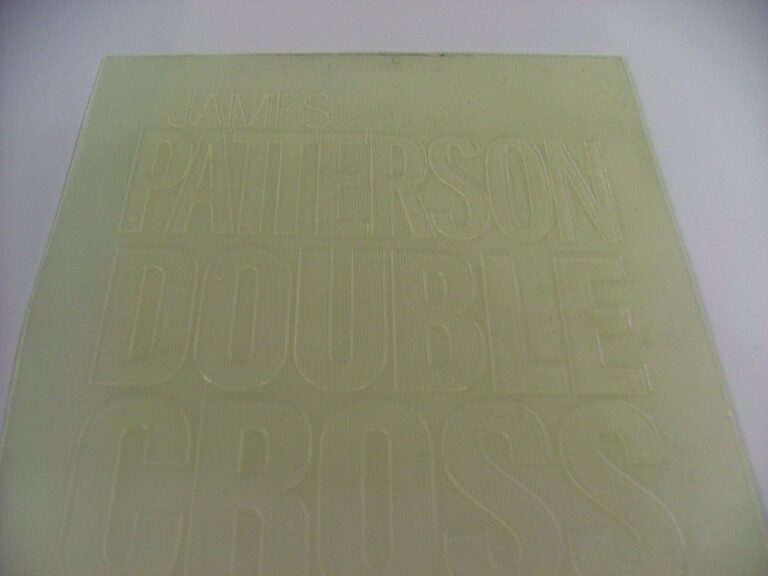

Plato Inline Epoxy Counterforce System PICX

Plato is an inline on the press system on making counterforces. Its quick system without the need for additional processing equipment as you can use 2 thick plates and clamps/clips. This system allows the user to make trade house quality counterforces inhouse.

Plato is a super-premium 1:1 liquid epoxy resin and hardener mix with low odour and superior structural strength, very hard wearing, so recommended for all production runs especially high.

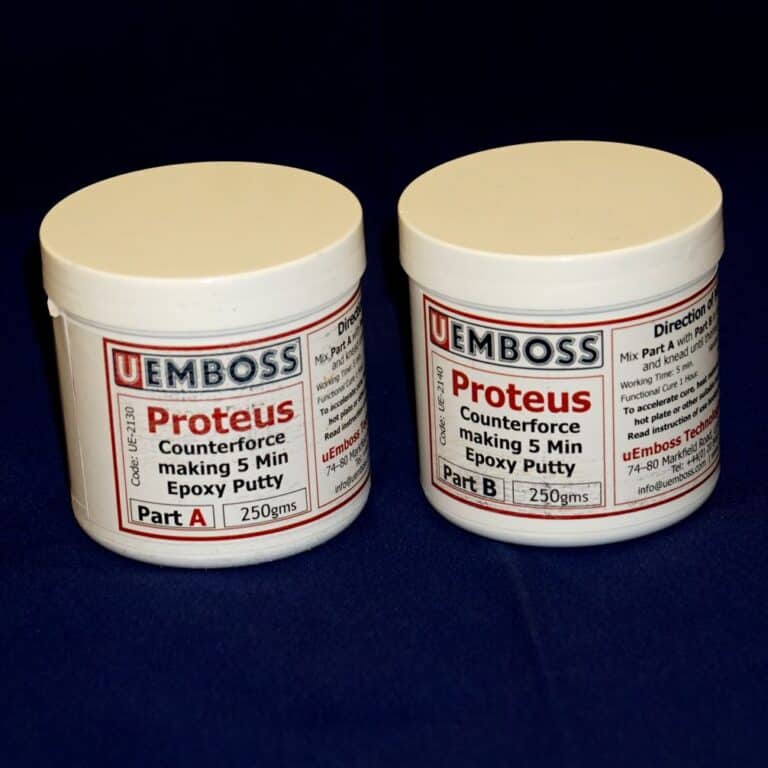

Proteus Inline Epoxy Putty Counterforce System (PTX):

Proteus is an inline on the press system on making counterforces. It can also be used with thick plates and clamps/clips off press. This product is an alternative to the liquid based 2-part epoxies Counterforces such as Plato with a strong bond to fibreglass backing boards and improved heat resistance.

Proteus is a super-premium 1:1 epoxy and hardener putty mix with low odour and superior structural strength, very hard wearing, so recommended for all production runs especially high. This product generally does not create air bubbles so very user friendly.

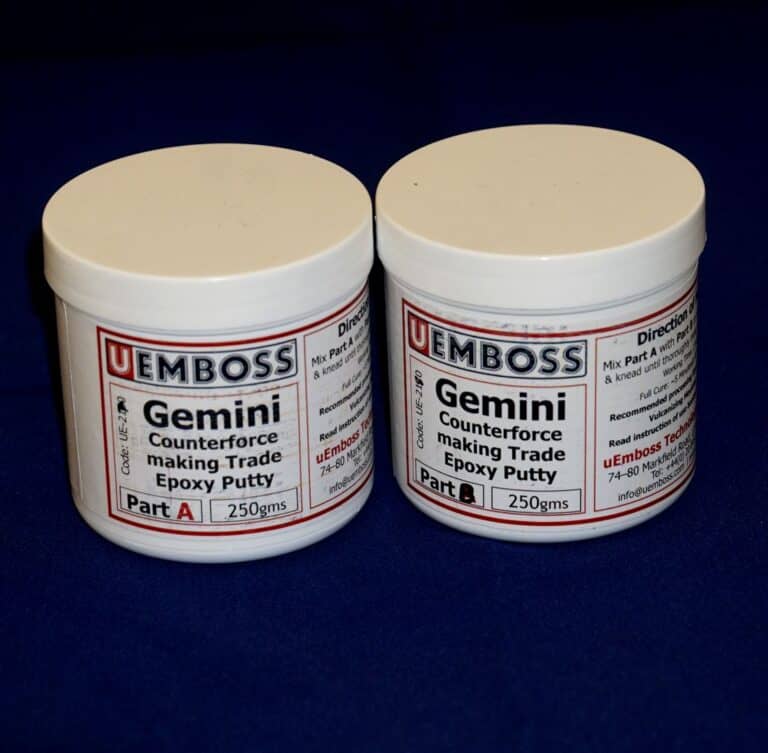

Gemini Trade Epoxy Putty Counterforce System (GTX):

Gemini is an alternative to the liquid based 2-part epoxies Counterforces (Troy & Helios), with a strong bond to fibreglass backing boards and improved heat resistance. The Gemini system requires a vulcanizing press and is recommended for trade houses.

Gemini is a super-premium 1:1 epoxy and hardener putty mix with low odour and superior structural strength, very hard wearing, so recommended for all production runs especially high. This product generally does not create air bubbles so very user friendly.

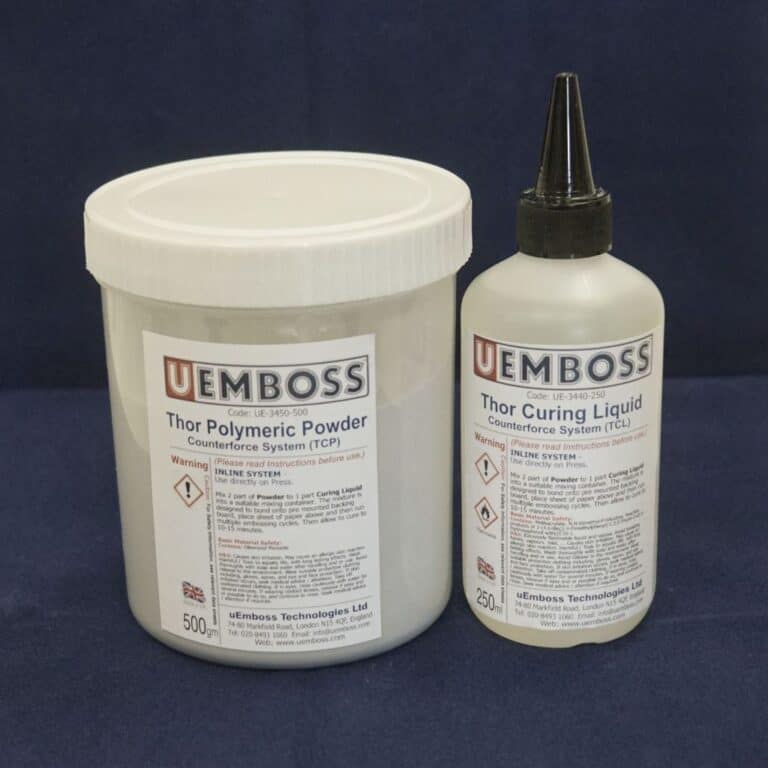

Thor Inline Polymer Counterforce System (TEX):

Thor is an inline on the press system on making counterforces. This is a liquid & Powder system that is very easy to make and use.

The mixture has a ratio of 2:1 and once mixed is applied to a pre-mounted base board on the press. A sheet of paper is placed over the applied paste and the press run slowly for 10 to 20 minutes by which time the mixture sets hard. The die and the newly set counterforce will be in exact registration with each other. Backing can be fibreglass boards, grey backing board or most matte surface untreated card.

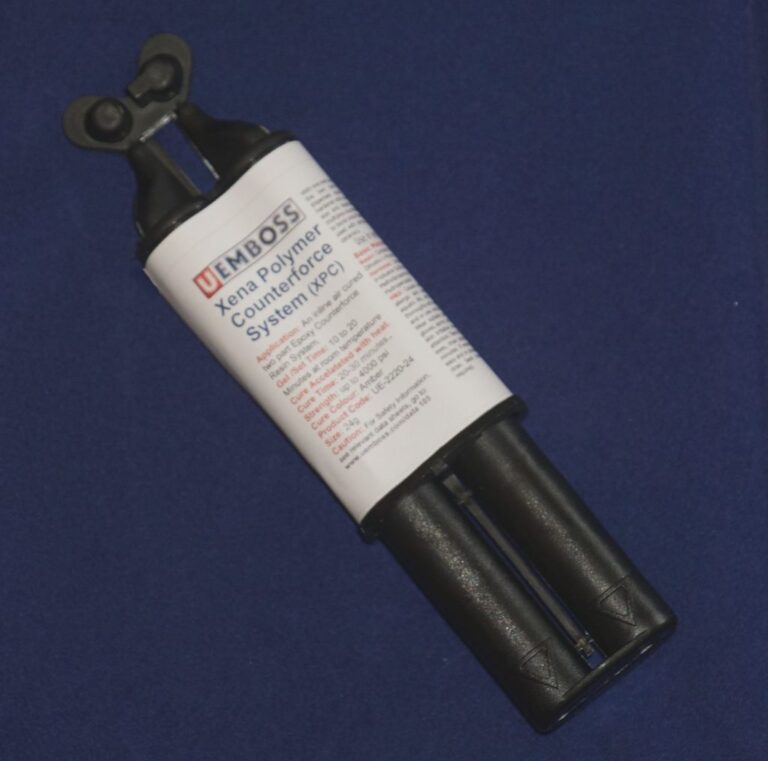

Xena Inline Polymer Counterforce System (XPC):

Xena is an inline on the press system on making counterforces. This is a liquid system that is very easy to make and use.

The mixture has a ratio of 1:1 dispensed from a 2-part cartridge and once mixed is applied to a pre-mounted base board on the press. A sheet of paper is placed over the applied paste and the press run slowly for 10 to 20 minutes by which time the mixture sets hard. The die and the newly set counterforce will be in exact registration with each other. Backing can be fibreglass boards, grey backing board or most matte surface untreated card.

Atlas-Matrix Trade Counterforce and Duplicate Making System (AMX):

Atlas-Matrix is a system developed for Trade houses but can be used in-plant if suitable equipment is available. A vulcanizing (moulding) press is required with a minimum 50 Ton pressure capacity.

This system involves a phenolic board and or phenolic powder. Three phenolic boards are used to produce ¼” / 6.35mm and or 7mm thick duplicate with the optional addition of the powder if very fine and or intricate designs are involved. One board with or without powder for rigid thick counterforces and powder only for thin hard counterforces.

A very simple and stable product with the duplicate staying flat for many years (If stored flat and correctly). The original male die or counterforce is required to mould the duplicate.

Leo Trade Duplicate Making System (LDX):

Leo is a polymer-based putty which can be used to make a duplicate.

Place putty on male mould and then compress on a suitable vulcanizing (moulding) press with a minimum 20 Ton pressure capacity. Please note, as a general rule of thumb, the larger the die the higher the tonnage required to compress the putty accurately. Heat cure the putty, allow to cool and separate trim and its ready to use.

Juno Duplicate Making System (JDX):

Leo is a polymer-based putty which can be used to make a duplicate.

Place putty on male mould and then compress on a suitable vulcanizing (moulding) press with a minimum 20 Ton pressure capacity. Please note, as a general rule of thumb, the larger the die the higher the tonnage required to compress the putty accurately. Heat cure the putty, allow to cool and separate trim and its ready to use.

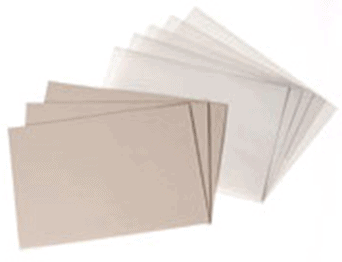

Libra Composite Embossing Board (LEB)

Pressure embossed composite sheets for Counterforce manufacture are easy to make and are more suitable for in-house manufacture and use.

Recommended for short Cold Embossing runs on paper and foil .