uEmboss Degassing Vacuum Chamber DVC-C1

The uEmboss DVC Counterforce Resin Degassing Vacuum Chamber is an essential piece of equipment for any company wanting to produce or are producing counterforces. Produce bubble free counterforces by de-aerating embossing resin.

A quick and effective system that is a must for every counterforce making facility.

- Low maintenance system.

- Cylinder chamber made of stainless-steel.

- Powerful vacuum pump for quick degassing of counterforce resin.

- Thick acrylicglass lid for rigidity and durability.

- Transparent acrylicglass lid for easy viewing of the degassing process.

- 900mm hose length as standard but can be easily replaced with a longer length.

- Built in silencer on vacuum gauge exhaust to reduce noise.

- Vacuum Chamber Lid Resting Base.

Removing air bubbles, slows down counterforce production. Using air blowers and air jets are fine for the persistent air bubbles or used for small throughput and or occasional use. For professionals and high throughput production companies, the air jet and blower are useful, but two other methods are more commonly used.

One method is to pre-heat the die, and then pour the resin onto the cavities of the design, and the heat causes the bubbles to pop. This is not a full proof method and relies on experience, and the other method is using a vacuum chamber. DVC – C1 vacuum chamber forces the air trapped or imbedded in the counterforce resin to come to the surface and pop. When mixing epoxy resins and other 2-part mix materials you will inevitably introduce loads of air bubbles.

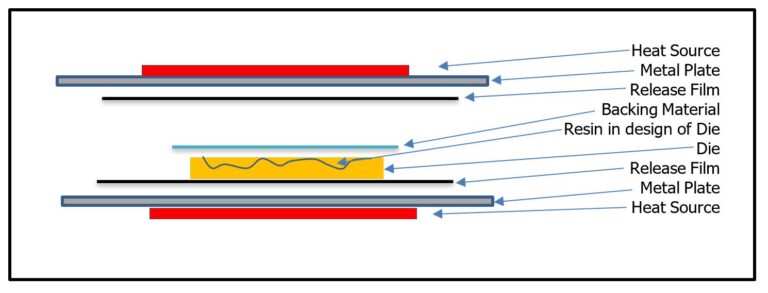

Using the cylinder chamber, you can degas and remove most if not all the air present in the resin. As an option, you can then pour the resin onto the die and then degas in the tray vacuum chamber to remove any air bubbles introduced when pouring and missed in the chamber. When placing the backing board on top of the die and resin, it is quite easy to introduce air bubbles. A vacuum chamber is an invaluable product to help improve quality, reduce frustration, increase speed of your die making process. All it takes is up to a minute in each chamber.

If using high viscosity resins you will find heating the mixed resin to around 50°C / 122°F, will help to reduce the viscosity and so help remove the trapped air bubbles. Both the resin and the hardener can be heated separately before mixing and will make it easier to mix.

DVC-C1 is a very simple to use piece of equipment which allows modular growth and flexibility. All you have to do is to mix the resin in a clear disposable cup and place the cup in the vacuum chamber (cup should not be more the half full). Then put the lid on and check that the valves are in the correct positions, and then switch on the vacuum pump.

Wait for 30 second to about a minute and once the air bubbles stop popping, switch off the vacuum pump and turn the valve to release the vacuum. Once the vacuum is released, lift off the lid and place on the Lid Resting Base and remove the plastic cup. Pour resin in the image area of the die and if required, though recommended, use the tray type vacuum chamber to degas again.

DVC vacuum chambers provides excellent value with a modular expansion architecture to expand with your growing needs. Stainless Steel vacuum chambers, heavy duty Acrylic lids, and quality parts used throughout. Spare parts available as assembles or individual components (spare parts not available for vacuum pump).

Cylinder:* ~ 220 mm (8.7”) Wide x 150 mm (5.9″) high

Recommended Working Area: Cylinder:* 110 mm (4.3”) x 95 mm (3.7”)

(*Dimensions are subject to change)

Air bubbles weaken the structure of the counterforce so it is important to remove as many as possible before placing the backing material on top of the resin.

Air bubbles occur when mixing resin, pouring resin and or placing backing material, and so great care must be taken to reduce the introduction of air.

Firstly, use a vacuum chamber to remove the bulk if not all the air trapped in the resin.

Pour resin into the design cavities of the die, use the air blower to remove any bubbles that form during the pouring process in the engraved or etched die.

If the temperature differences between the embossing die and the resin, is very large, then thermal shock can occur. It can happen when the resin makes contact with the die, the resin will release trapped microscope air bubbles which join up to produce large bubbles. When using the air blower to burst air trapped in the resin, it is sometimes difficult to see the bubbles properly so a torch or a side lamp can be used to seek them out.

This is where a secondary tray type vacuum chamber is handy as it will remove additional air bubbles on the die created when pouring the embossing resin or left in the resin in the cylinder vacuum chamber. The tray type (DVC – T1) is also useful in removing any air trapped when placing the backing boards.

When placing backing boards on top of the die, it is extremely easy to introduce air bubbles between the die and the backing board. Experienced operators rarely have this problem and should be considered more as a last resort then an automatic requirement.