Cost of Dies and Counterforces from Die Makers

Cost of Counterforces

Lots of Die makers use low cost materials to make counterforces because their customers want it for cheap. By saving a few pennies on the counterforces could be actually costing the users a lot more on make ready, breakages and other issues and not even realise that fact.

Die makers have costs too, they have to invest in very expensive capital equipment and very expensive upkeep, the building including all the costs that goes with it, and all the cost relating to highly skilled staff.

You as a customer too have similar issues and as your customers squeeze you on price you squeeze your supply chain. As we are all well aware you can only go so far, and yes, there is always someone to undercut your current supplier. Why is your current supplier unable to match or better the lowest bid ?

There could be a number of reasons:

- Don’t want to supply below cost

- Wants to still be in business years from now

- Want to provide quality and service.

- Wants to make a reasonable profit as you yourself wish to do

- Wants to pay his staff a decent salary

- Wants to run a modern operation in clean modern premises

- Wants to upgrade equipment and or expand

- Wants to have a safety prioritized business

All the above and more requires a reasonable income. Your current Die maker didn’t chase you for your business because they didn’t want to get your business as a lost leader and then profit from you in other ways…

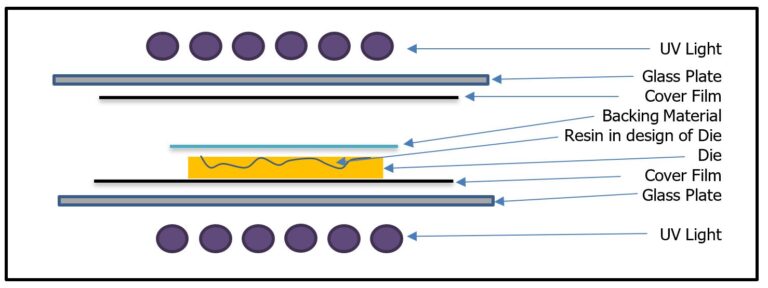

If price is very critical then why not just make the counterforce yourself and where it is just a 2½D design, you can make a Polymer plate as a die and mount it on a backing plate so it is to the required height. See information on in-house counterforce and Die Making.

Inhouse manufacture of some if not all your die and or counterforces can have many benefits that you wouldn’t normally realise.

- · Overall cost and time

- · Make in advance or Just in Time

- · Easing production bottlenecks

- · Flexibility

- · Improved work flow

- · Last minute design changes

- · Last minute breakage

- · Specification errors

- · Logistical issues and costs

- · and many other obvious and unexpected benefits……

Talk to us at uEmboss and we will open your eyes with possibilities.