Typical Pre-made Counterforce Issues

When ordering dies from a Die Maker you generally order matching counterforces as well. Sometimes you will encounter issues with the counterforces. Below are typical but not necessarily a comprehensive list of issues a user can encounter and mess up your work flow.

Problems:

- Embossing Counterforces too soft.

- Counterforce delaminating from backing material.

- Broken or cracked counterforce.

- Incorrect counterforce sent with details missing.

- Counterforce lost or not sent with order.

- Poor fitting counterforce.

- Wrong thickness of counterforce backing board.

- Time delay to get replacement Counterforce.

- Counterforce issue after 5:00pm and die maker closed till next day or Monday.

- Multi-up job and machine set up to run but issue(s) with one or more counterforces.

- Last minute design change on a urgent job.

- Replacement counterforce(s) not turned up in the post.

- Wrong quantity of Dies and Counterforces received from Die Maker for an urgent job.

- Wrong die ordered / supplied on an urgent embossing job.

- Mistake on the die on an urgent embossing job.

- Wrong type of counterforce sent by Die Maker

- and more……..

Some of the above situations may not have happen to you, does not mean it couldn’t. Things that could go wrong generally do, and it is usually a case of when, rather than if. Typically things go wrong when you can least afford the delay. Delays, cost expensive labour and machine time, that can cost far in excess of the cost of bringing counterforce making in-house, even if it is only for making emergency counterforces.

Counterforce making has been de-skilled by uEmboss, so most competent individuals could make then, quickly and easily. With a number of different systems, some just for Die Makers, some for in-house use and others for both. We have a variety of solutions starting from less than £50.00 upwards and are only a phone call or e-mail away to helping you select the right system for your company. Our systems are suitable for occasional, right up to mass production counterforce making, with products suiting all budgets. We provide detailed step by step instructions of use on all our systems and some systems in addition have highly detailed Instruction Manuals.

Through uEmboss and previously through our sister companies, we have been making counterforce materials and solutions for over 35 years with the widest range of counterforce making products from a single company globally. With that comes 35 years of experience and technical support in helping our customers all over the world successfully make counterforces and take control of the weak link in their embossing operations.

Problems and Solutions on Counterforces #1

- Embossing Counterforces too soft.

- Wrong type of material used to make the counterforce. The material used is for making cold embossing dies as the material softens with heat.

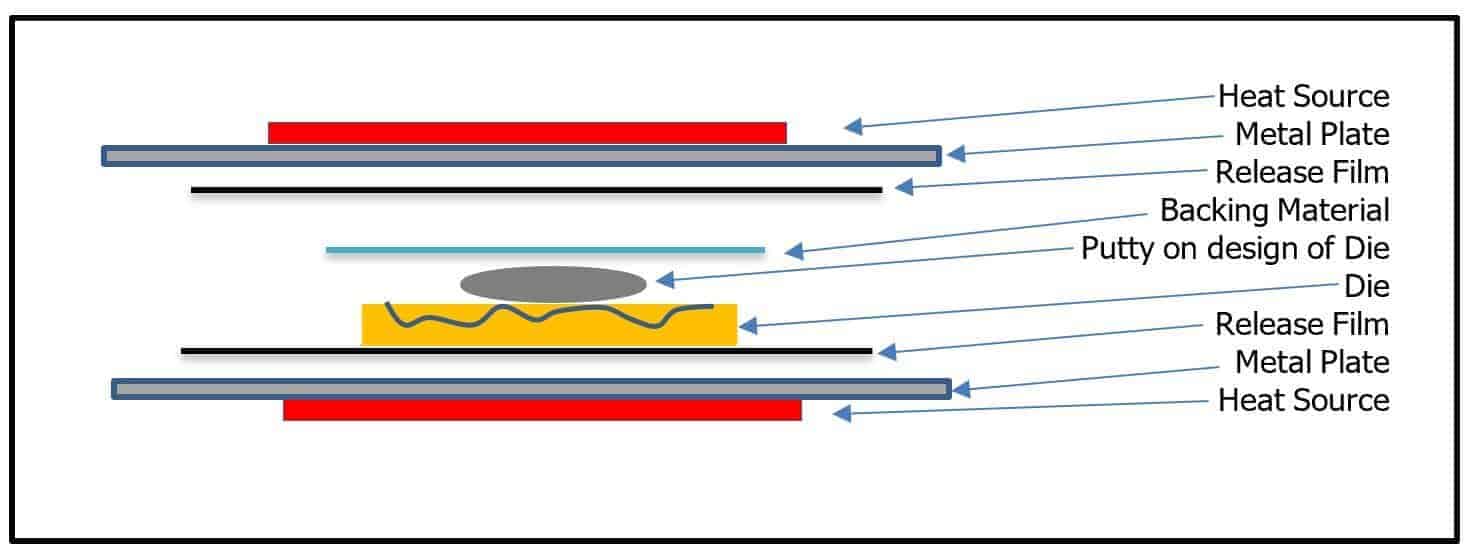

- Counterforce not cured properly. If heat cured material then you need to apply heat to cure properly. If UV cured material then counterforce must be cured with UV light.

- Counterforce delaminating from Backing material.

- Broken or cracked counterforce.

- Incorrect counterforce sent with details missing.

- Poor fitting counterforce.

- Wrong thickness of counterforce backing board.

- Wrong type of counterforce sent by Die Maker

Damaged while mounting on the press.

- Miss-alignment on the press.