Laying Backing Material onto Resins and Putties

Laying backing sheet or board on the counterforce materials needs to be done correctly or you will encounter numerus problems with air bubbles and voids. This will weaken the bond strength between the backing materials and Counterforce materials. Below are examples of different ways of doing this.

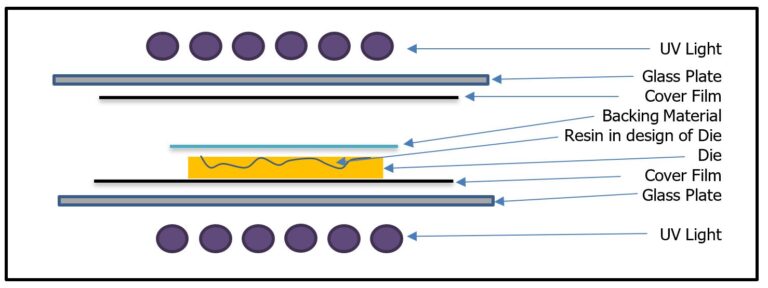

Photos are taken using the Ultra Counterforce system on the PEC A2 UV Counterforce Exposure Unit but the method of placing backing material also apply to all the other counterforce systems such as PICX, Troy, Helios, Titan, Proteus, Gemini, Zeus Etc.

It is recommended that your starting line where the backing material first make contact with the Counterforce material is slightly higher then the rest. This helps prevent air traps and fills in any low points.

Roll from one side: Suitable for backing sheet and thin backing board.

Roll from the centre: Suitable for backing sheet and thin backing board.

Lay from one side: Suitable for thicker boards.

Coiled from one side: Suitable for thin backing material’s such as polyester backing sheet and 0.2 mm fibre glass board.

Manipulating air bubbles: Using your finger gently push on the backing material above the bubble and manipulate the air bubble off the die.

Other Relevant Data sheets: Removal of Air bubbles from Resins, Delamination etc.