How to make Ultra UV Embossing Counterforce

ByuEmboss

Process of making Ultra UV Embossing Counterforces:

- First make or order in your Die. Your die can be made using our Embossing grade Photopolymer Plate or an etched, hand chiseled or a CNC engraved metal Die.

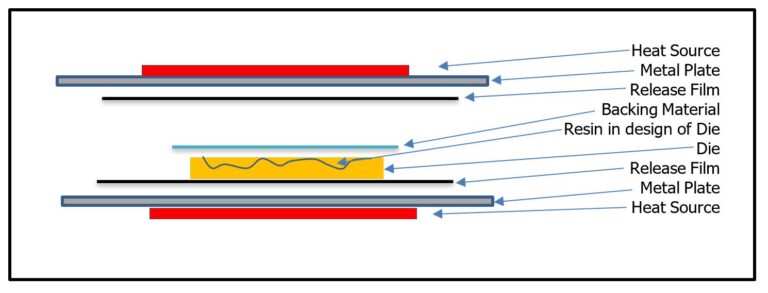

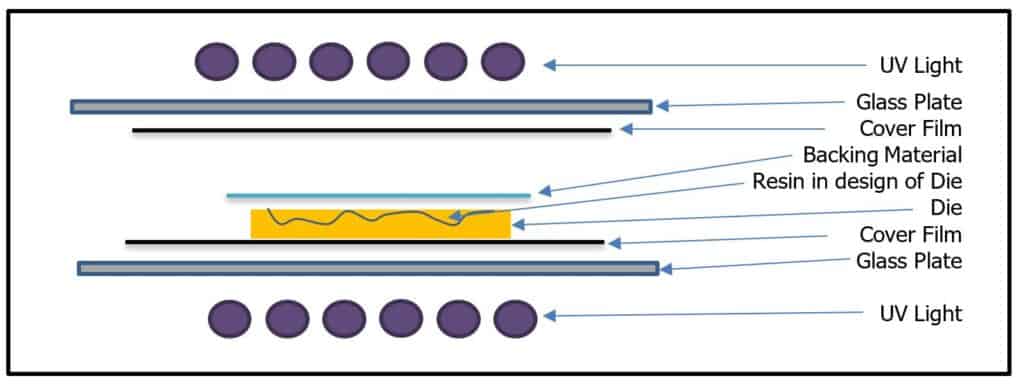

- Place a sheet of suitable oversized Cover Film on the base glass of the UV exposure unit.

- Spray or apply release agent on the Die.

- Place the Die on to the Cover Film.

- Pour Embossing resin onto the Die. Ensure sufficient resin is poured, to prevent voids forming.

- Remove any air bubbles formed during pouring with a hair dryer or air blower.

- Place coated rough side of the Backing Sheet or Board on top of the resin filled Die.

- Place another sheet of suitable oversized Cover Film on top of the backing material.

- Bring top glass against the Die and Counterforce materials and bring to pressure, to ensure a flat even Counterforce.

- Exposure to UV light preferably from both sides, for the required time. That will cure the Counterforce resin and bond to its backing material.

- After the resin is cured, lift up top glass and wearing suitable gloves remove Die and cured Counterforce from the UV exposure machine.

- Once removed from the exposure unit, separate the Counterforce from the Die and trim to the required size